Technology Research and Development

FGBIOKO is a leading provider of belt drive system technology in China. It has extensive experience in the technical aspects of belt tensioners, idlers and fan supports, including system simulation, design and development, individual product verification, system verification and mass production.

We focus on the matching development technology of accessory drive systems and products, as well as the research and exploration of product performance. In terms of high performance, high reliability and high cost performance, we outperform our peers’ products.

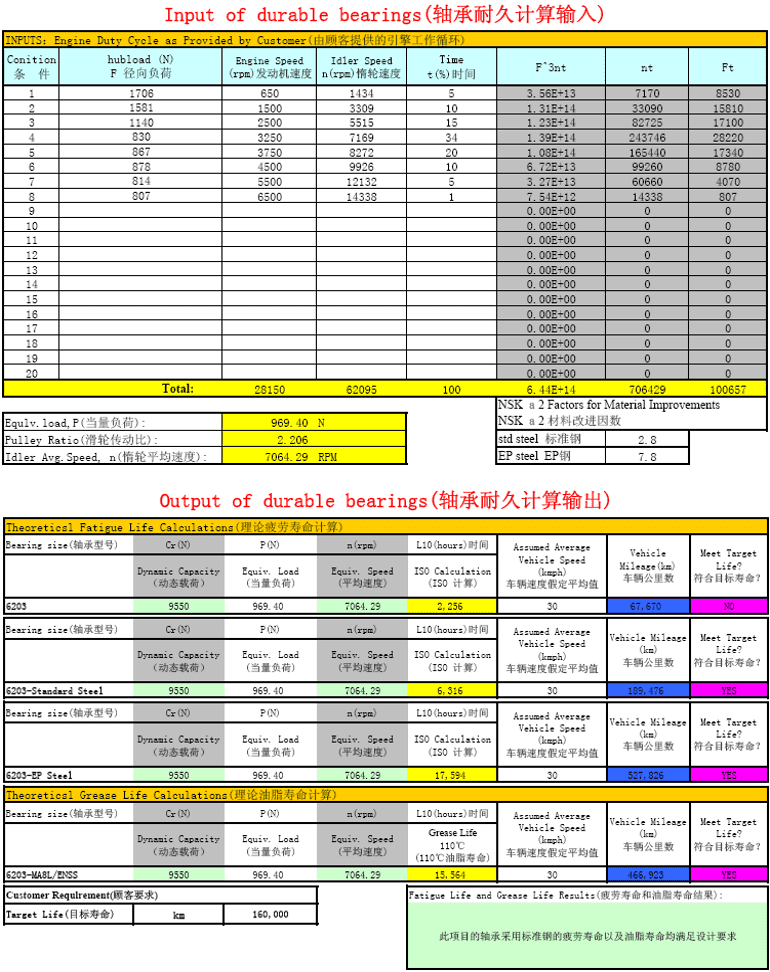

Design Input

Wheel Train Design

Product Development

Part Test

Vehicle Test

Design Input

Basic data parameters

1.Engine Type

2.Engine Displacement

3.Numbers of Cylinders

4.Engine Speed

5.DMFW or Not

6.Shock-absorber for Crankshaft and ALT or Not

Geometric parameters of the engine wheel train

1.Coordinate Position of Each Accessory

2.Diameter of Crankshaft and Belt Pulley

3.Space for Engine Accessories (3D Model)

4.Special Requirements for Tensioner Installation

Engine crankshaft parameters

1.Moment of Inertia of Engine Crankshaft

2.Angular Vibration Curve of Engine Crankshaft

Engine accessory parameters

1.Moment of Inertia of Engine Accessories

2.Power Consumption Curve of Engine Accessories

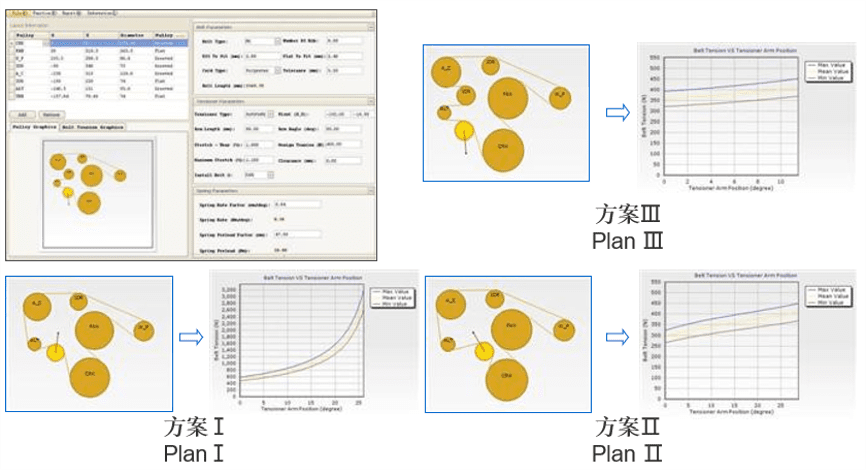

Wheel Train Design

Accessory drive system layout matching: According to the design criteria, select the best layout scheme through various different layouts.

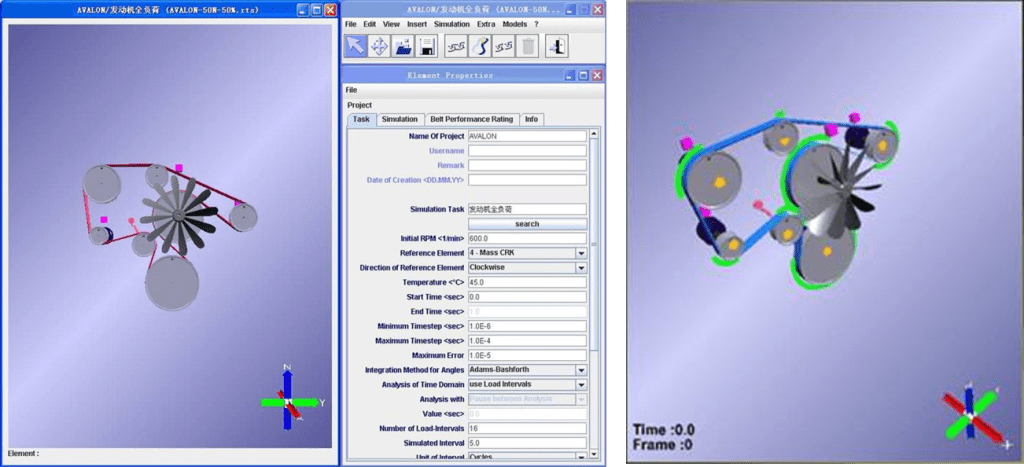

Accessory drive system simulation matching: According to the design criteria, simulate and match the best system and product performance.

Product Development

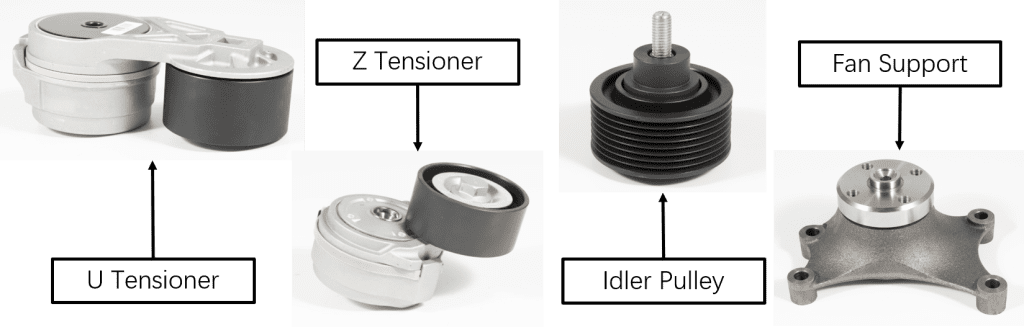

Product Structure Type

Based on the customer’s requirements, select the best product structure types such as belt tensioner pulleys, idler pulleys, and fan brackets

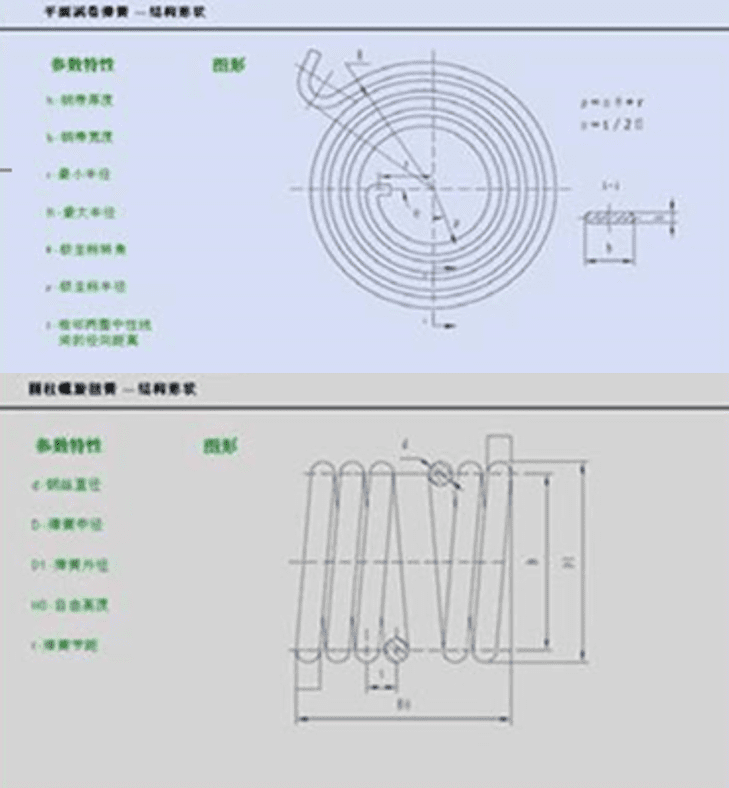

Spring structure type

Select the best spring structure type based on the customer’s boundaries and performance requirements.

Bearing Structure Type

Select the best bearing structure type based on the customer’s boundary, working conditions and performance requirements.

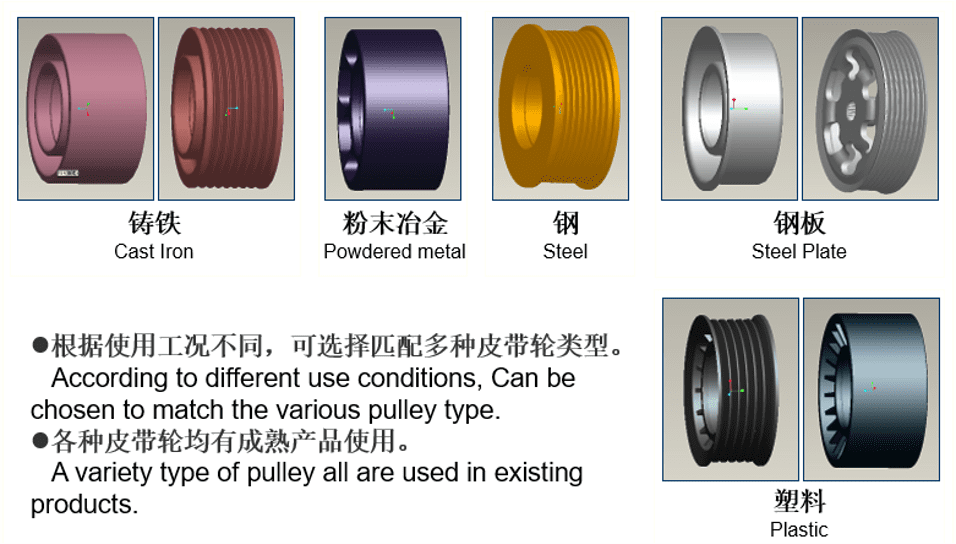

Various Pulley Types

Based on the customer’s requirements, select the best pulley structure type.

Patent Certificates

We have 31 authorized patents and 5 patents of invention. There are another 4 patents of invention are under review.

Part Test

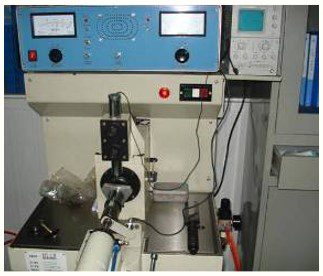

Tensioner Torque Test

Tensioner Durability Test

Idler Pulley& Fan Support Durability Test

Tensioner Thermal Cycle Durability Bench Tester (SAE STD)

Tensioner Salt Spray Bench Tester (SAE STD)

Pulley Noise Test

Bearing Test

Corrosion Test

Salt Spray Test

Ozone Test

Pully Impact Test

Homeostasis Test

Hot & Cold Test

Other Tests:Fast Recovery, Drop Test & Vibration Test etc.

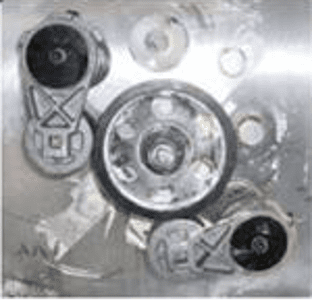

Vehicle Test

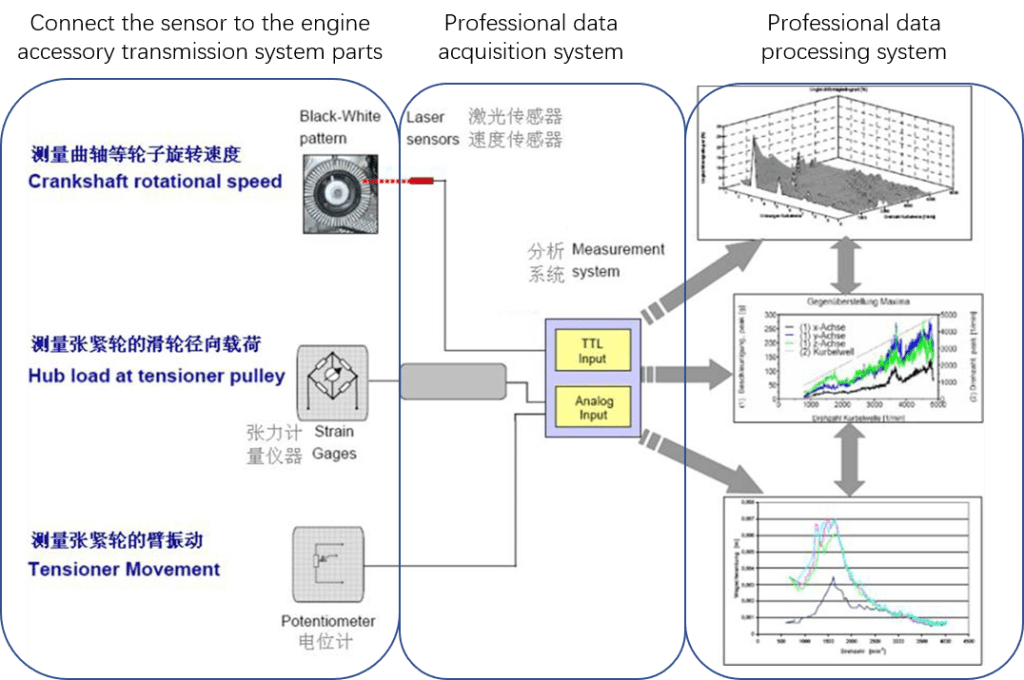

The performance data of the accessory transmission system can be collected on the customer’s complete vehicle or engine test bench. After data processing and analysis, the system performance of the put into production complete vehicle can be verified to meet the requirements of the end user.

Principle of Data Acquisition

Test Case

On-site Test:Engine Bench Test

On-site Test:Vehicle Proving Ground